A Digital Twin is a virtual representation that replicates a physical object or process over a period of time. It allows you to monitor and command systems and components remotely, and run simulation models. In addition, a digital twin is a replica of a real-world entity that helps in predicting, optimizing, and improving decision-making.

Digital Twins let users simulate real-world conditions and see the outcomes instantly on any platform, including mobile devices, computers, and AR/MR/VR devices. Each digital twin deployment is unique and can range from a 3D model of a product component to a precise representation of a network.

The history of Digital Twin

The “Digital Twin” idea was presented in 2002 but has been well-known since the 1960s. NASA used to fabricate physical twins of spacecraft to simulate the physical-mechanical assemblies operating outside of the Earth’s environment, but nowadays, such system layouts have become virtual rather than physical.

Although Digital Twin technology has gained massive popularity in the past few years, the concept is not entirely new. In 2002, Michael Grieves, Executive Dir/Chief Scientist Digital Twin Institute, proposed a model for Product Lifecycle Management (PLM) that had three components: real space, virtual space, and a linking mechanism for the flow of data/information between the two.

Digital Twin trend

According to Markets and Markets, North America is one of the early adopters of digital twin technology and is expected to grow at the highest CAGR from 2022 to 2027.

The automotive & transportation industry is expected to account for the largest share of the global digital twin market by 2027. This is primarily due to the increasing usage of digital twins in vehicle designing, simulation, maintenance, repair, overhaul, production, and after service.

North America is expected to hold the largest share of the digital twin market throughout the forecast period, due to the presence of major digital twin providers and the increasing demand for advanced technologies in the automotive, aerospace, chemical, energy & utilities, and food & beverage industries.

Industries seeing remarkable results from Digital Twin

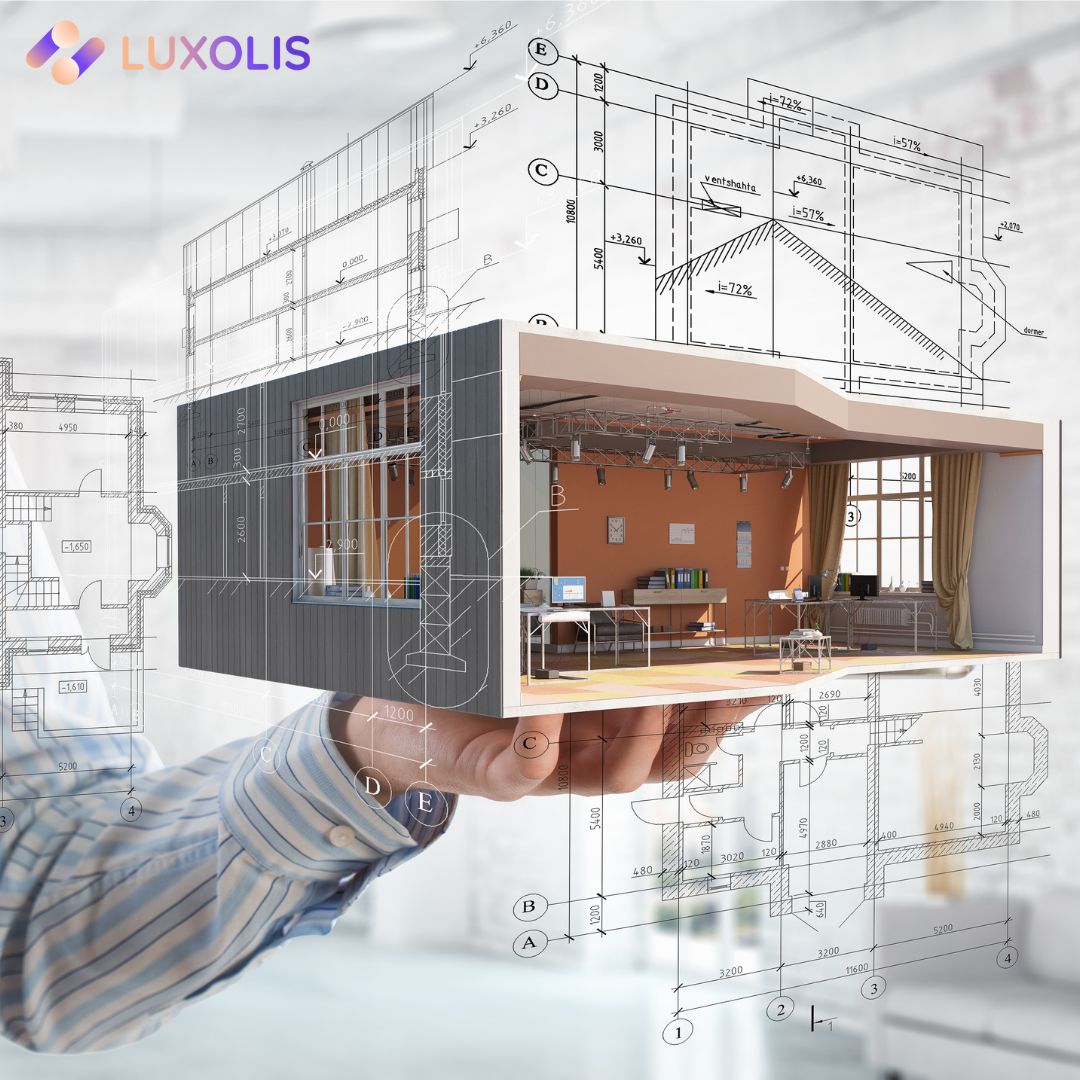

Construction

Construction crews can use digital twins to plan out projects and understand how they’re coming along, in real-time. This allows for revisions and changes to be made without delaying the entire build.

Using the Luxolis 3D Scan App throughout the entire construction process not only keeps a project on track and within budget but also eliminates risk.

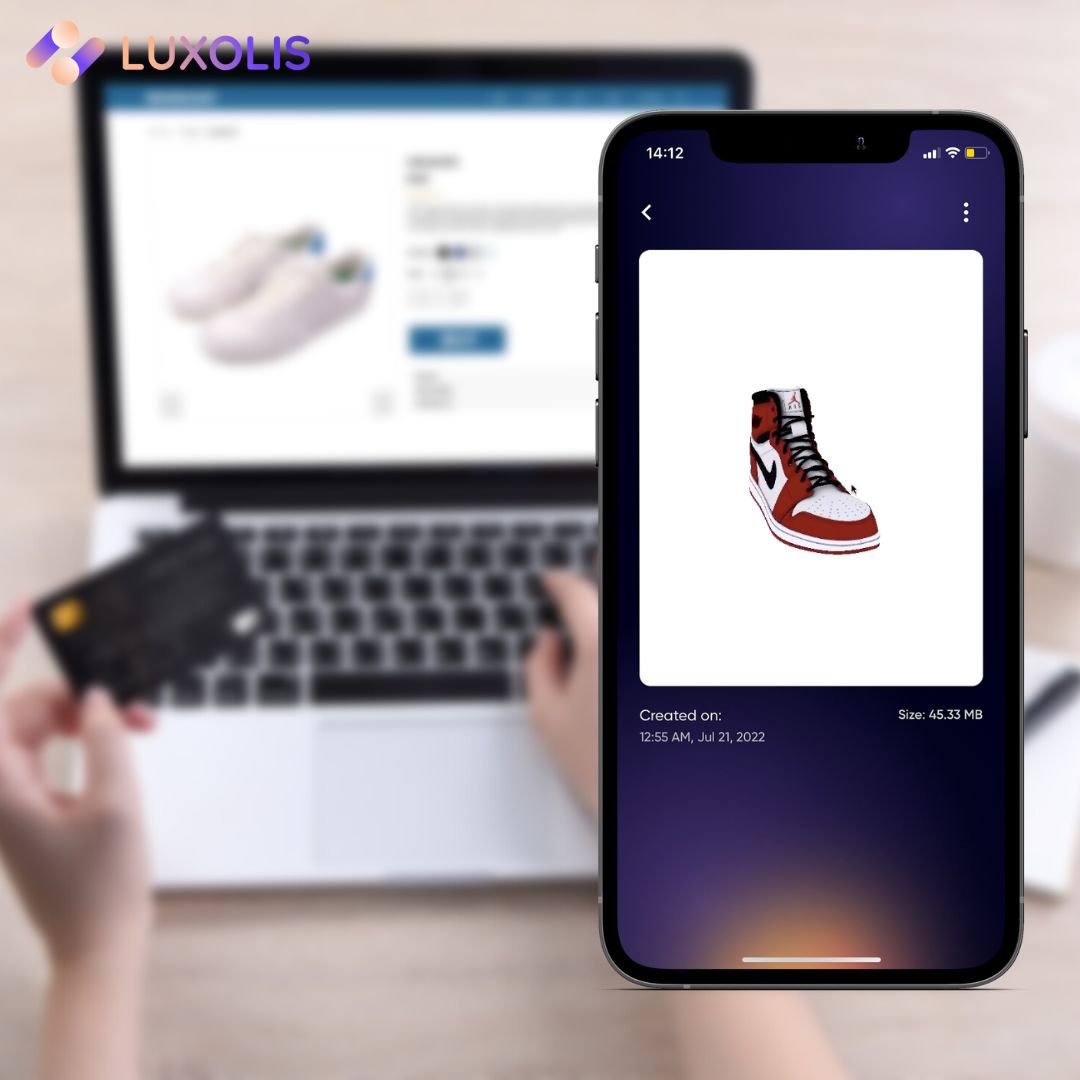

E-commerce

eCommerce success depends on accurate product representations. With 3D digital shopping, the customer can interact with the products as if they were in front of them, instead of simply scrolling through images and product descriptions.

The 360° rotation allows customers to get a more hands-on, interactive experience by zooming in and rotating around a product.

If you design your products in 3D, that means you are one step ahead of the competition!

Automotive

Digital twins help auto manufacturers test their vehicles before they ever make it onto a testing track or physical roadways. Before entering the market, vehicles must undergo some mandatory design and control stages. Initially, designers model the vehicle’s exterior and interior before designing its components.

Using a Digital Twin, you can simulate the existence and functionality of various systems and provide valuable insight into their compatibility, performance, and interoperability.

Real Estate

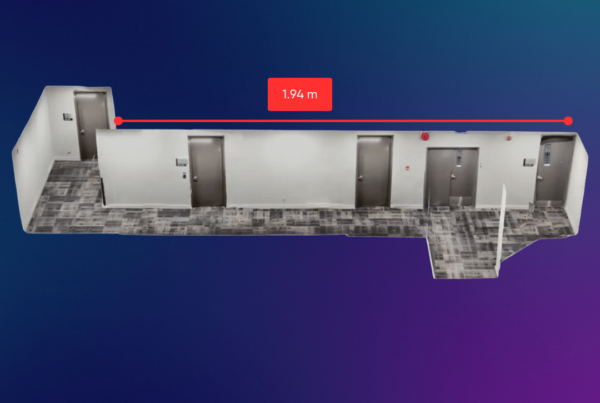

3D virtual tours using Luxolis OpenAir technology allow sellers to stage their home once, and then present a virtual open house 24/7.

Imagine your potential buyer lives in another country or city and can’t visit the property to take a tour. With Digital Twin, the buyer can see each room on each floor, read highlights, ask questions, and even take measurements.

Luxolis 3D Scan App is a fantastic tool for agents to identify buyers and sell properties faster.

Manufacturing

The manufacturing industry is revolutionized by digital twins, which enable product development, unique design, at-scale personalization, predictive maintenance, and more.

Product development engineers can use virtual prototypes to test the feasibility of planned or upcoming projects before they’re launched, and even before running trials or consumer testing.

Healthcare

A Digital Twin of a hospital can be created to help optimize patient care, cost, and performance. This allows informed strategic decisions to take place in a highly complex and sensitive environment.

Digital Twin technology can be used to create personalized medicine by modeling an individual’s genomic makeup, physiological characteristics, and lifestyle. It is more advanced than precision medicine, which focuses on sample groups within the population.