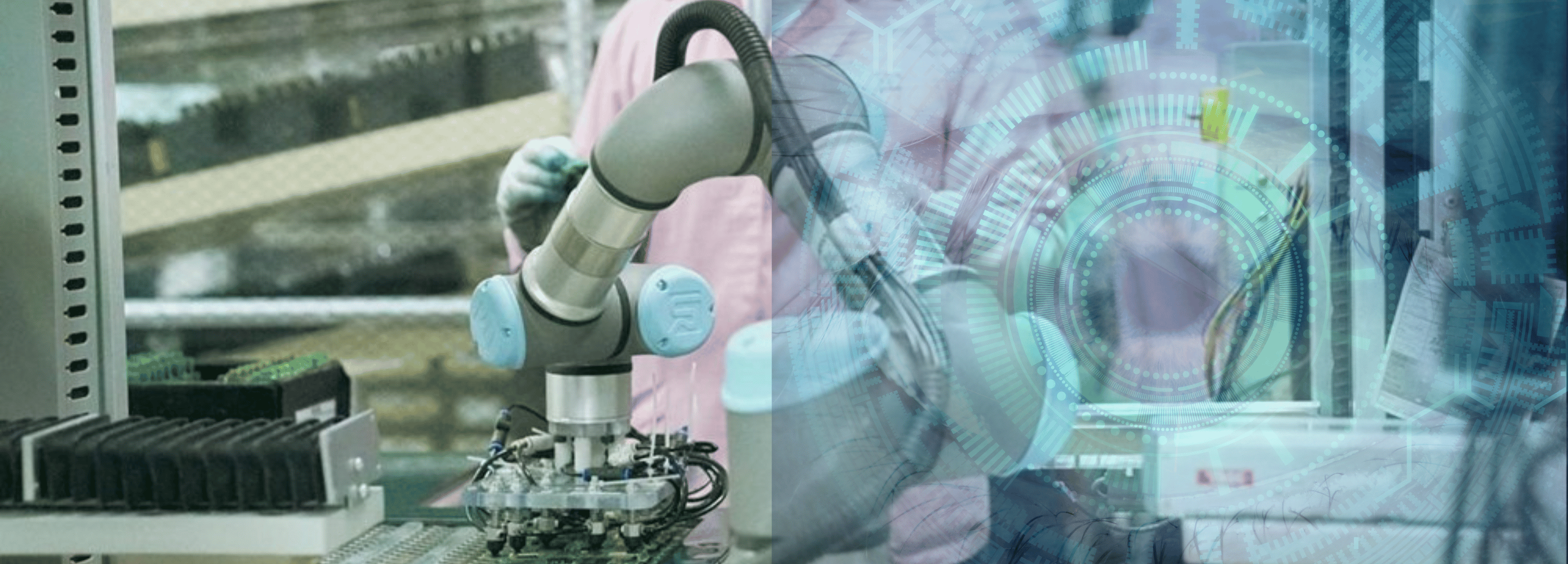

Collaboration between humans and robots is rapidly growing, driving innovation and efficiency in various industries. By integrating 3D vision systems from Luxolis AI with collaborative robots (cobots), we are enhancing Electrostatic Discharge (ESD) testing in the electronics manufacturing sector. Our 3D vision technology can accurately detect and locate components, thus ensuring cobots’ precise and efficient ESD testing without the risk of unwanted collisions – all while working seamlessly alongside human colleagues. This transformative approach not only enhances safety and productivity but also sets new standards for quality and reliability in the industry.

In the dynamic landscape of electronics manufacturing, precision and efficiency are paramount. ESD testing stands as a critical checkpoint in ensuring the reliability and safety of electronic components. Luxolis AI, a leading innovator in machine vision solutions, is spearheading a groundbreaking project with a renowned electronics manufacturer to automate ESD testing using state-of-the-art vision solutions integrated with cobots.

ESD testing is performed to test the susceptibility of ICs and electronic devices to electrostatic discharge. ESD tests are broadly divided into device- and system-level tests. These are go/no-go tests that simply determine whether equipment under test (EUT) is destroyed by ESD.

Addressing Specific Challenges: Automation with Precision

Luxolis AI’s team of engineers is currently tackling the intricacies of ESD testing head-on, focusing on specific tasks to streamline the process effectively, addressing both the vision systems and cobot aspects.

Collision Detection

In the era of collaborative robotics, where cobots are designed to work alongside humans, ensuring safety is paramount. Collision detection using sensory feedback not only allows for predictions and the detection of upcoming collisions beforehand but also significantly reduces workplace injuries and equipment damage. Furthermore, with the ability for real-time adjustments and optimal path planning, collision detection ensures uninterrupted operation and efficiency in dynamic work environments.

Tool Change Mechanism

There are two ESD Test Types: airgun test and touch test. To perform one or another task different gun tips are used. Our team is working on a mechanism enabling swift tool changes, allowing the cobot to adapt to different stages of the ESD testing process efficiently. For instance, it facilitates the quick exchange of testing probes (gun tips) to accommodate various testing requirements.

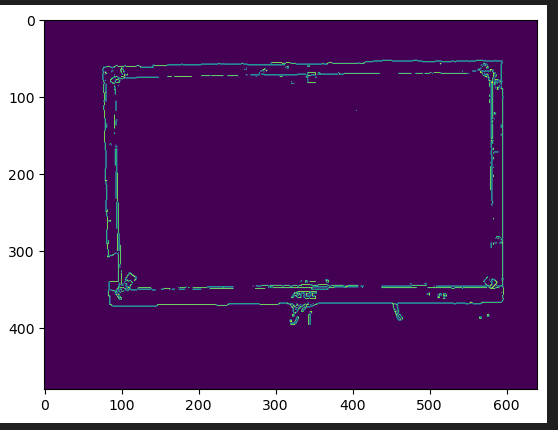

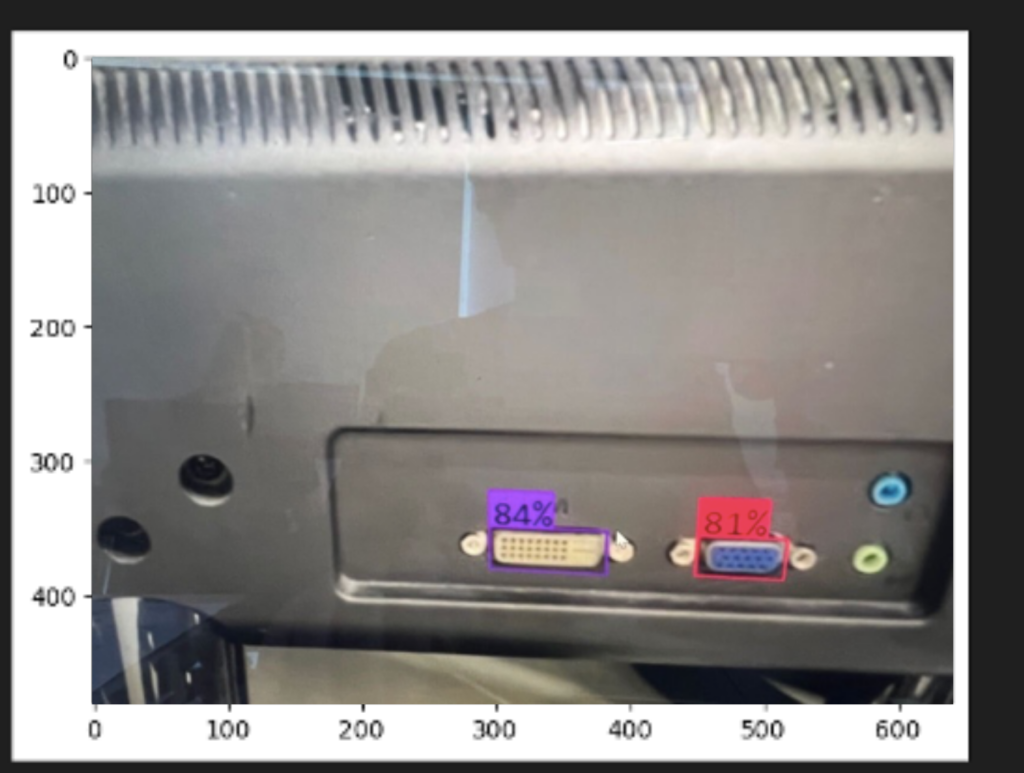

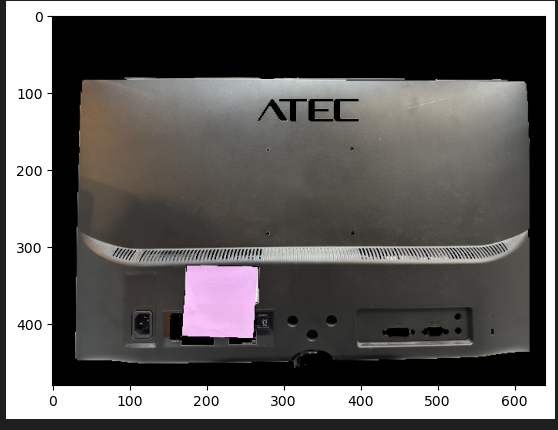

Edge and Object Detection

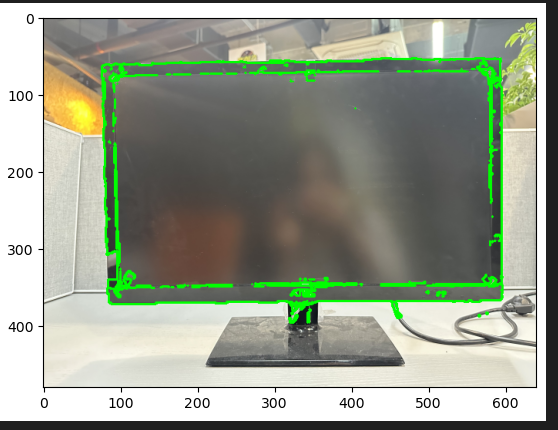

Leveraging the power of 3D vision systems to accurately identify the boundaries and testing points of electronics such as a computer monitor to ensure precise targeting during the ESD tests and minimizing the risk of testing errors.

Edge Detection: 3D vision systems equipped with edge detection algorithms can accurately identify the contours of electronics components and classify them. This ensures that the ESD testing probes are precisely positioned, minimizing the risk of testing errors and ensuring consistent contact with the correct areas of the components.

Object Detection: Object detection capabilities enable the machine vision system to recognize and locate specific components and testing points on the electronics circuit boards. This allows the cobots to perform targeted ESD tests, avoiding unnecessary movements and reducing the overall testing time.

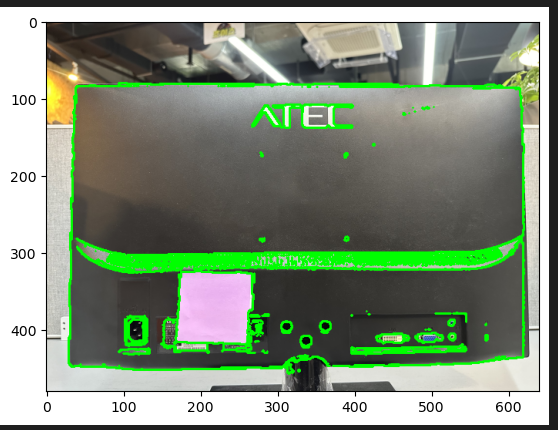

Object Background Detection

Using computer vision and image processing tools with AI capabilities, we can distinguish objects from the background. This allows for more accurate object detection and edge detection, enhancing the overall precision of the ESD testing process.

Luxolis AI’s endeavor to revolutionize ESD testing through the integration of 3D vision cameras with cobots marks a significant leap forward in electronics manufacturing. By combining cutting-edge technology with precision engineering, Luxolis AI continues to pave the way for transformative changes in the industry, setting new standards for efficiency, reliability, and innovation.

Contact Us Today

Ready to transform your manufacturing processes with cutting-edge automation? Contact us at hello@luxolis.ai, discover how Luxolis AI can enhance your operations with advanced machine vision solutions. Let’s innovate together and elevate your business to new heights of efficiency and reliability!